I recently have been lucky enough to put my hands on the VW Haldex Service Training – Self Study Program (no. 89C303). And since I get a lot of questions about it, here’s the integral document. (Haldex section) BTW, it’s as good for the Audi TT Haldex.

Enjoy!

Andre

PS Also see: HPA’s Haldex Performance Controller and Haldex Controller Update: Blue – Orange – Silver Controllers.

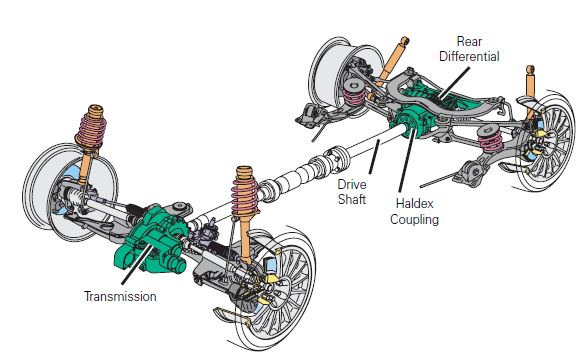

Haldex Coupling

The development of the Haldex coupling is a giant step forward in modern all-wheel-drive technology. This coupling is controllable, based on the inputs the Haldex control module receives from the vehicle. Slip is no longer the only decisive factor in the distribution of drive forces — the car’s dynamic state is also a factor. The Haldex control module monitors the ABS wheel speed sensors and the engine control module (accelerator pedal signal) via the CAN-bus. This data provides the engine control module with all the information it needs on road speed, cornering, coasting or traction mode, and can respond optimally to any driving situation.

Characteristics of the Haldex coupling:

• Permanent all-wheel drive with electronically controlled multi-plate clutch

• Front drive characteristic

• Quick response

• No strain on clutch when parking and maneuvering vehicle

• Compatible with different tires (e.g., emergency wheel)

• No restrictions on towing with the rear axle on the ground

• Fully integrates with systems such as the Anti-Lock Brake System (ABS), Electronic Differential Lock (EDL), Anti-Slip Regulation (ASR), Electronic Brake Distribution system (EBD), and Electronic Stabilization Program (ESP)

The Haldex coupling is mounted on the rear axle differential and is driven by the drive shaft. Engine torque is transmitted to the drive shaft through the gearbox, the front axle differential, and the front axle drive The drive shaft is connected to the input shaft of the Haldex coupling. In the Haldex coupling, the input shaft is separated from the output shaft to the rear axle differential. Torque can only be transmitted to the rear axle differential when the Haldex coupling clutch plates are engaged.

Haldex System

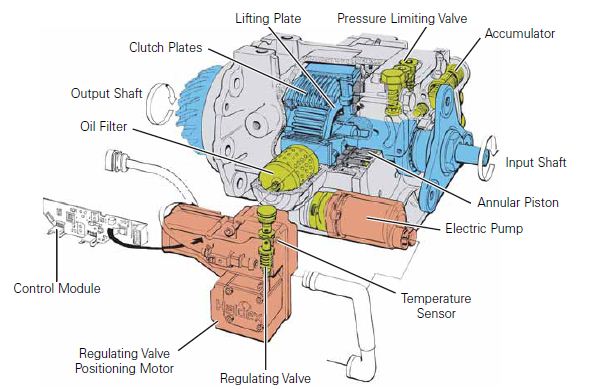

The parts include:

• Input shaft

• Inner and outer clutch plates

• Lifting plate

• Roller bearing with annular piston

• Output shaft

The electronics are:

• Pump for Haldex coupling

• Regulating valve positioning motor

• Temperature sensor

• Haldex control module

The hydraulics are:

• Pressure valves

• Accumulator

• Oil filter

• Annular piston

• Regulating valve

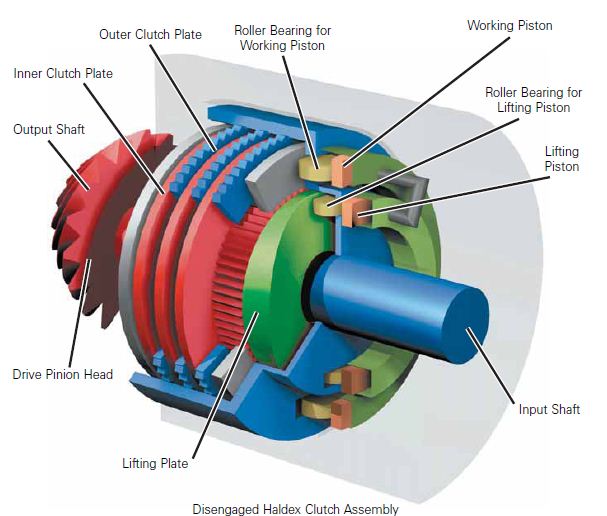

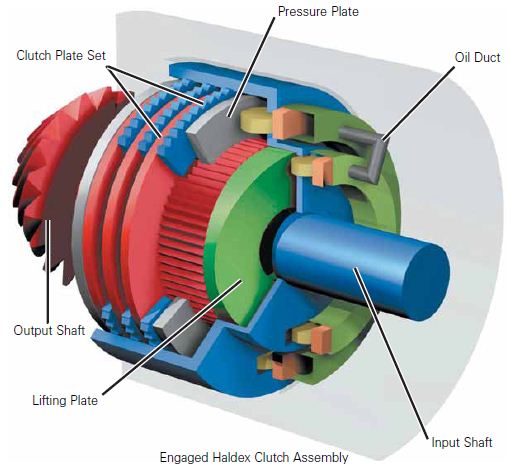

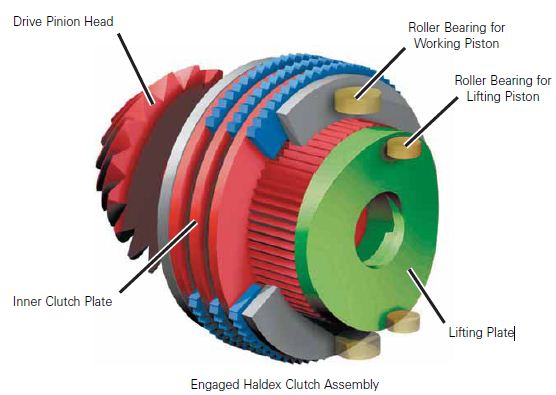

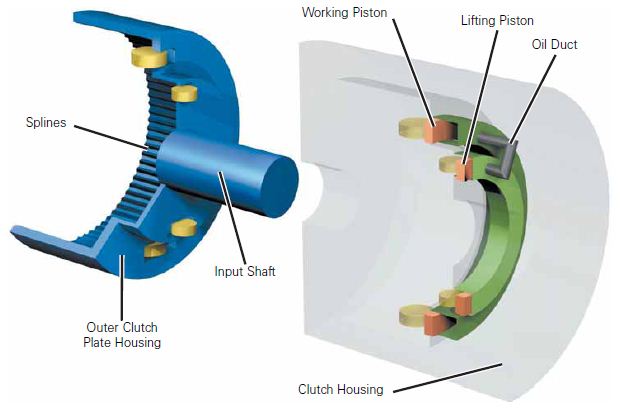

Multi-Plate Clutch The clutch input shaft, indicated in blue in the illustration below, is connected to the prop shaft. The roller bearings for the lifting piston and the working piston, as well as the outer clutch plates, are engaged when the input shaft rotates.

The lifting and working pistons are annular pistons. The output shaft, indicated in red in the figure, forms a unit from the lifting plate through to the drive pinion head. The inner clutch plates are also connected to the output shaft via longitudinal toothing.

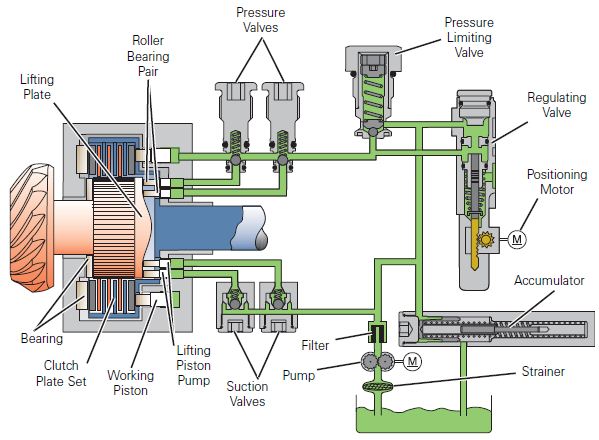

Function When a speed difference is present between the input and output shafts, the input shaft, together with the roller bearing of the lifting piston, rotates around the still stationary lifting plate of the output shaft. The roller bearing of the lifting piston tracks along the undulating surface of the lifting plate. The roller transfers these upward and downward movements to the lifting piston, causing it to perform a lift movement, building up oil pressure.

Oil pressure is diverted via an oil duct to the working piston, forcing the working piston to move to the left against the roller bearings and the pressure plate of the clutch plate set. The clutch plate set is compressed. The input shaft and the output shaft of the clutch are now interconnected, connecting both the front and rear axles and making allwheel drive possible.

When a difference in speeds occurs between the front and rear axles, the outer clutch plate housing, together with the roller bearings, rotates around the output shaft in such a way that the roller bearings of the lifting piston roll on the lifting plate.

Due to the shape of the lifting plate, the roller bearings of the lifting piston follow an undulating path and transfer the lifting movement to the lifting pistons in the housing.

The output shaft, with its splines for the inner clutch plate, combines with the lifting plate and the drive pinion head to form a unit.

! The roller bearings are shown here for your information only.

! For reasons of clarity, we have shown the lifting plate with two cams. In reality, there are three cams on the lifting plate. The function remains unchanged.

The outer clutch plate housing, together with the splines for the outer clutch plate and roller bearings, combine with the input shaft to form a unit.

The movement of the lifting piston produces an oil pressure which acts on the working piston via the oil duct, pushing the piston to the left.

Pressure is transferred via a pressure plate to the clutch plate set and the roller bearings of the working piston. The clutch closes and thus interconnects the front and rear axles.

! The roller bearings are located in the outer clutch plate housing, as shown here. These roller bearings are shown here for your information only.

Diagram of the Oil Pressure System

The pressure limiting valve determines the maximum pressure on the clutch plates.

You have already seen how oil pressure is built up at the lifting piston as a result of a difference in speeds between the input shaft (blue) and the output shaft with lifting plate (red).

This oil pressure is regulated by valves. The clutch plate can thus allow a certain amount of slip when open and nearly closed.

! For reasons of clarity, we explained function on the previous pages using a lifting piston by way of an example. In reality, there are two lifting pistons in the clutch housing — these pistons are actuated by roller bearing pairs. Therefore, two suction valves and two pressure valves are also required.

Motronic Engine Control Module (ECM) J220

This control module is mounted in different areas on the various vehicles, but is normally accommodated in the plenum chamber. The operating mode of J220 is torque-oriented.

Signal Utilization for the All-Wheel Drive Electronics

J220 provides the following signals to the All-Wheel Drive (Haldex) Control Module J492 along the CAN-bus:

• Engine speed signal

• Accelerator pedal position

• Engine torque

Effects of signal failure:

• The Haldex coupling will not operate

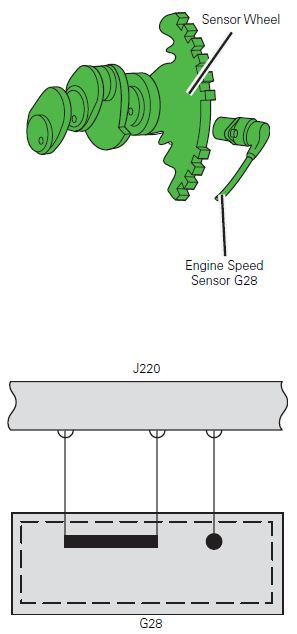

Engine Speed (RPM) Sensor G28

G28 is an inductive sensor and is installed near the oil filter on the left-hand side of the engine.

Signal Utilization

This sensor records in the exact angular position of the crankshaft to determine the ignition and injection point, as well as engine speed.

Engine Speed

As soon as the engine turns, the sensor wheel moves past G28 and generates an alternating current (AC) voltage. The frequency and amplitude of this voltage changes with engine speed.

Motronic ECM J220 calculates engine speed from the frequency of the AC voltage.

Ignition Point

To recognize crankshaft position, the sensor wheel has a larger gap trigger tooth which serves as a reference mark.

ffects of Signal

Failure If the engine speed signal supplied by G28 fails, the engine will not start or run.

If no engine speed signal is received, the Haldex control module J492 will not energize the pump, leaving rear axle drive capability disabled. This also allows the vehicle to be towed with the rear wheels on the ground because no power is transmitted back through the wheels to the transmission.

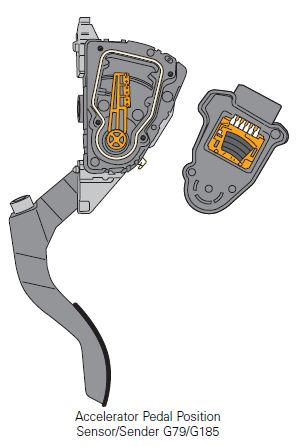

Throttle Position Sensor G79 and Sender 2 for Accelerator Pedal Position G185

Two independent potentiometers, G79 and G185, work together to receive and send accelerator pedal position analog signals to Motronic ECM J220.

Haldex control module J492 uses these signals in combination with other signals to determine when and how much power should be applied to the rear axle. G79 and G185 represents the driver intention, and is not necessarily how J220 is allowing the engine to operate.

Effects of Signal Failure

J220 monitors G79 and G185 for proper functioning and plausibility. If one of these two fails, the other sensor/sender acts as a back-up. The Electronic Power Control (EPC) Warning Lamp K132 on the instrument cluster will illuminate and the vehicle will enter emergency running mode.

If this signal is not available to the Haldex control module J492, all-wheel drive will not be available.

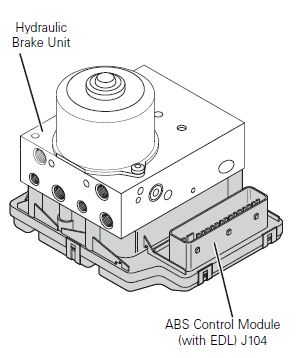

ABS Control Module J104

This control module is combined with the hydraulic unit, which is mounted in the engine compartment on the left-hand side. When the ignition is turned on, the control modules carry out a self-test.

This control module consists of two processor systems, which ensures a high level of fail-safety. In addition to monitoring individual components, the two processor systems monitor each other.

Signal Utilization for All-Wheel-Drive Electronics

The following signals are supplied to the Haldex control module J492 along the CANbus:

• ABS Wheel Speed Sensors G44 and G47

• Brake Light Switch F9

• Parking Brake Light Switch F9

• Longitudinal Acceleration Sensor G251

Effects of Signal Failure

In the unlikely event of total failure of the control module, the Haldex unit will not function properly.

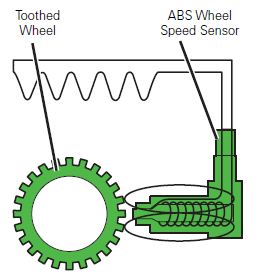

Right Rear and Left Front ABS Wheel Speed Sensors G44 and G47

These sensors detect changes in wheel speed, sending this information to ABS Control Module J104 in the form of wheel speed information. This information is then sent to Haldex control module J492 via CAN-bus.

Each wheel speed sensor is mounted in the vicinity of the axle flange. A toothed wheel is positioned on the axle flange in such a way that it moves past the top end of the wheel speed sensor when the wheel rotates.

Magnetic lines of force between the tooth and tooth gap of the toothed wheel are distorted. This induces a sine-wave AC voltage in the coil of the engine speed sensor.

The frequency and amplitude in the coil is dependent on wheel speed. J104 calculates the momentary speed of individual wheels from the frequency. Effects of signal failure:

• No ABS control

• No all-wheel drive control

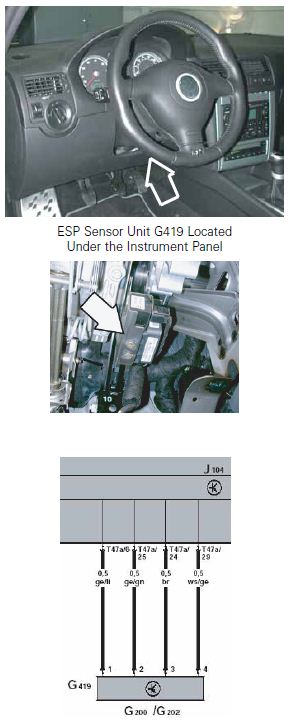

ESP Sensor Unit G419

ESP Sensor Unit G419 combines the functionality of two sensors, Sensor for Transverse Acceleration G200 and Sensor for Rotation Rate G202. This combined sensor is located on a bracket in the steering column area, under the instrument cluster. G419 is able to measure both transverse acceleration and rotational rate or yaw.

Effects of Signal Failure

Without the measurement of transverse acceleration or rotational rate, it is not possible for the ABS Control Module J104 to determine if ESP intervention is necessary. As a result, ESP and ASR will not operate, and the ESP light will illuminate in the instrument cluster.

Electrical Circuit

G419 is connected to J104 via four wires.

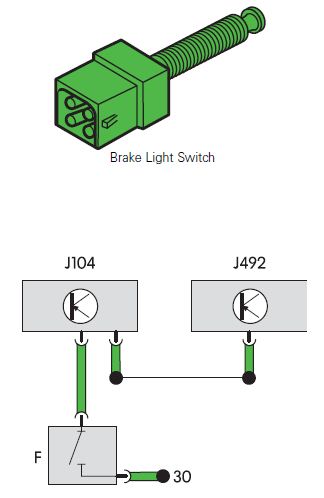

Brake Light Switch F

This switch is located at the upper end of the brake pedal and is secured to the pedal support.

Signal Utilization

This brake light switch sends the “brake activated” signal to ABS Control Module J104, which informs Haldex control module J492 along the CAN-bus.

When the brake is applied, J492 immediately opens the pressure regulator via the positioning motor, opening the Haldex coupling clutch.

Effect of Signal Failure

The information provided by the CAN-bus is used as an alternative.

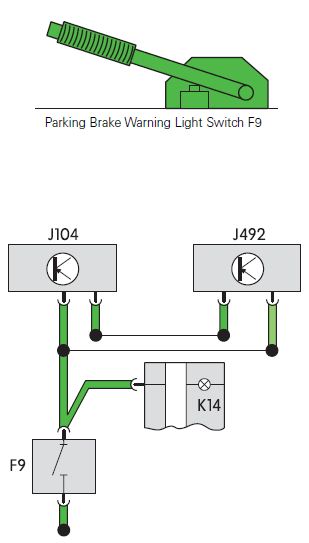

Parking Brake Warning Light F9

This switch is located under the parking brake lever.

Signal Utilization

F9 sends the “parking brake engaged” signal simultaneously to ABS Control Module J104 and the Haldex control module J492.

If the signal generated by F9 is picked up, the Haldex coupling clutch is opened.

Effects of Signal Failure

If the switch remains closed, then no allwheel drive control is available and restrictions are placed on ABS control.

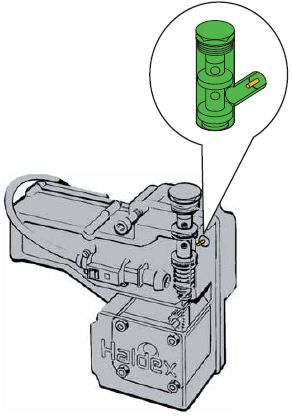

Hydraulic Temperature Sensor G271

This sensor is installed near the regulating valve in the Haldex control module J492 housing and is immersed in hydraulic fluid.

Signal Utilization

G271 senses current hydraulic oil temperature, sending this information to J492. This information is used for constant adaptation to the changing hydraulic fluid viscosity.

If the hydraulic fluid temperature exceeds 100°C, the clutch is released. If the temperature of the hydraulic fluid drops below 100°C, the clutch is again pressurized.

Effects of Signal Failure

All-wheel drive is shut off if no signal is received from G271.

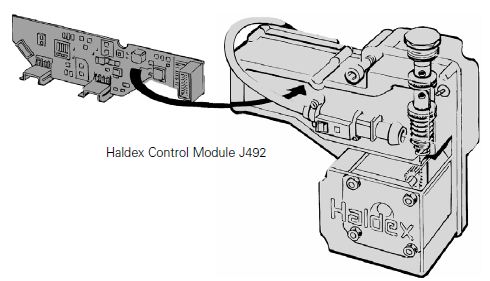

All-Wheel Drive (Haldex) Control Module J492

This control module is mounted directly on the housing of the Haldex coupling and combines with the positioning motor and the regulating valve to form a unit.

Design and Function

J492 is connected to the engine and ABS control module J104 via the CAN-bus. From the signals that are generated by Motronic ECM J220 sensors, J492 decides what oil pressure to apply to the plates of the Haldex coupling clutch.

The oil pressure acting on the plates of the Haldex coupling clutch determine what torque is to be transmitted to the rear axle.

Effects of Signal Failure

If J492 is not operating correctly, no all-wheel drive is possible.

! Use address word 22 to access All-Wheel Drive (Haldex) Control Module J492.

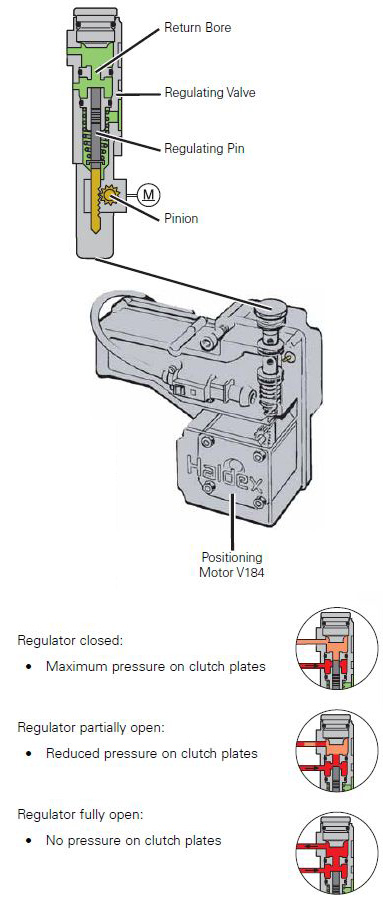

Oil Pressure Actuator V184

This positioning motor is integrated in the Haldex control module J492 housing.

Design and Function

V184 is supplied with voltage by J492 and functions as a stepping motor.

At the command of J492, the positioning motor changes the level of the regulating pin in the pressure regulator via a small pinion gear.

The level of the regulating pin changes the cross section of a return bore in the pressure regulator. This controls the pressure acting on the working piston, and in turn, on the clutch plates.

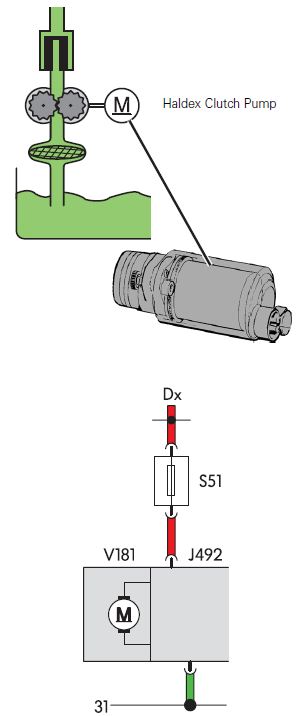

Haldex Clutch Pump V181

The pump for the Haldex coupling is attached to the Haldex coupling housing.

Design

After the engine has been started, the pump for the Haldex coupling is supplied with voltage by Haldex control module J492 as soon as engine speed exceeds 400 rpm.

Function

The pump for the Haldex clutch conveys oil to the lifting piston and brings the lifting piston into contact with the lifting plate via roller bearings.

At the same time, oil reaches the working piston. This eliminates any play from the clutch plate set and ensures quick clutch response.

Effects of Signal Failure

If V181 is not operating correctly, no all-wheel drive is possible.

! The Haldex clutch pump is directly supplied with voltage by J492.

Self-Diagnosis

Haldex self-diagnosis electrically monitors:

• Signals generated by the sensors

• Activation of the positioning motors

• Haldex control module J492

If J492 detects a fault, it calculates a substitute value from other signals and makes an emergency running program available.

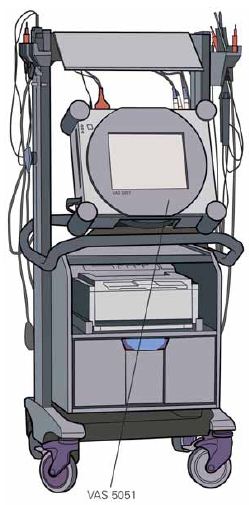

In the data transfer facility, the following functions can be read out under the address word 22 “4-wheel-drive electronics” via the VAS 5051 or VAS 5052:

02 Check DTC Memory

03 Output Diagnostic Test Mode (DTM)

05 Erase DTC Memory

06 End Output

08 Read Measuring Value Block